Choosing between an air-cooled and a water-cooled electromagnet is not just a thermal decision.

It directly affects continuous operation time, magnetic field stability, acoustic noise, and long-term maintenance cost.

This article explains the real trade-offs laboratories should understand before requesting a quotation.

1. Why Cooling Method Matters More Than Field Strength

Many users start with a simple requirement:

“We need a 1–2 Tesla electromagnet.”

In reality, cooling defines how long and how reliably that field can be maintained.

Two magnets with the same nominal field can behave very differently once duty cycle, temperature rise, and noise are considered.

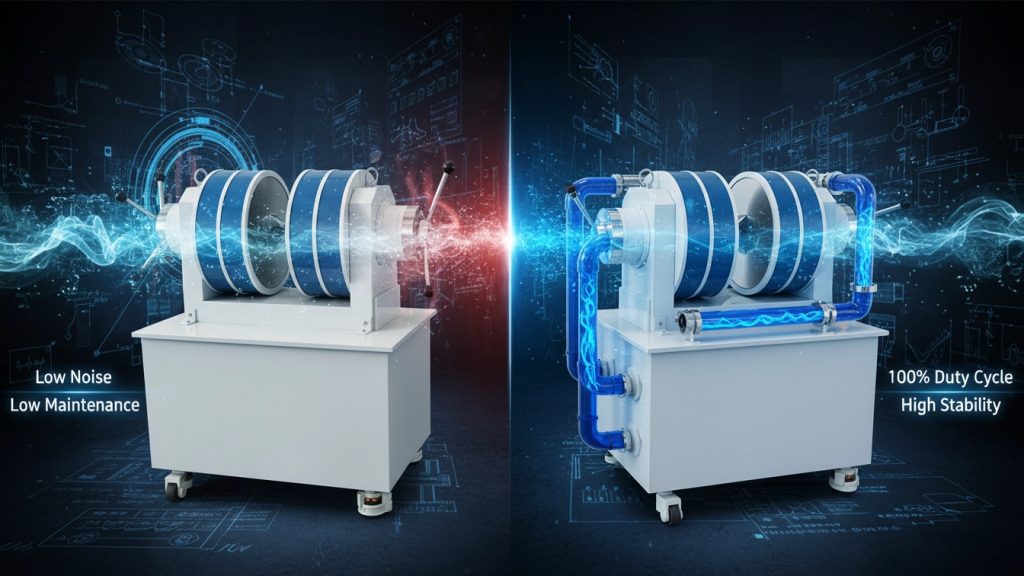

2. Air-Cooled Electromagnets: Simple, Quiet, and Limited

How Air Cooling Works

Air-cooled electromagnets rely on:

- Natural convection

- Forced air flow using fans

Heat is removed from the coil surface and iron yoke into the surrounding air.

Key Advantages

- Simple installation

- No external cooling infrastructure

- Lower upfront cost

- Minimal leak risk

Practical Limitations

- Limited continuous duty cycle

- Coil temperature rises faster at high current

- Field drift increases during long measurements

Typical Use Cases

- Intermittent experiments

- Educational laboratories

- Low to medium field strengths

- Short measurement durations

3. Water-Cooled Electromagnets: Designed for Continuous Operation

How Water Cooling Works

Water-cooled electromagnets circulate coolant directly through:

- Hollow copper conductors

- Embedded cooling channels

This removes heat much more efficiently than air.

Key Advantages

- High continuous duty cycle

- Stable coil resistance and field output

- Lower thermal drift during long experiments

Engineering Trade-Offs

- Requires external chiller or cooling loop

- Higher installation complexity

- Maintenance of hoses, filters, and flow sensors

Typical Use Cases

- Long-duration measurements

- High-field operation

- Industrial testing and calibration labs

- Cryogenic or vacuum-integrated systems

4. Duty Cycle: The Hidden Specification Most Users Miss

Duty cycle defines how long a magnet can operate at a target field without exceeding safe temperatures.

- Air-cooled systems: often 10–30% duty cycle at high field

- Water-cooled systems: commonly 100% duty cycle

If your experiment runs hours instead of minutes, cooling choice is no longer optional.

5. Acoustic Noise and Lab Environment

Air-cooled magnets often rely on fans:

- Fan noise can affect sensitive measurements

- Vibrations may couple into probes or fixtures

Water-cooled magnets:

- Quieter during operation

- Noise mainly from external chillers, which can be isolated

For low-noise magnetic measurements, cooling strategy directly impacts data quality.

6. Maintenance and Lifetime Cost Comparison

Air-Cooled Systems

- Minimal routine maintenance

- Fan replacement over long term

- Lower operational cost

Water-Cooled Systems

- Periodic inspection of cooling lines

- Water quality management

- Higher reliability under heavy load

The right choice depends on total cost of ownership, not just purchase price.

7. How Cryomagtech Helps You Choose the Right Cooling Strategy

Cryomagtech designs and supplies both air-cooled and water-cooled electromagnet systems, matched to:

- Target magnetic field

- Required duty cycle

- Noise constraints

- Laboratory infrastructure

👉 Product link placeholder: Cryomagtech Electromagnet Systems & Cooling Options

We help translate experimental requirements into cooling-safe, stable field solutions.

References

- Wikipedia – Electromagnet

https://en.wikipedia.org/wiki/Electromagnet - IEEE – Thermal considerations in electromagnetic devices

https://ieeexplore.ieee.org/

Key Takeaways

- Cooling method defines duty cycle and stability

- Air cooling favors simplicity and low cost

- Water cooling enables continuous, high-field operation

- Correct cooling choice prevents drift and downtime

Choosing the wrong cooling method is one of the most expensive mistakes in magnet procurement.