Hall effect measurements are fundamental in materials science and semiconductor research.

They are widely used to extract carrier type, carrier density, and mobility.

However, many experiments fail not because of poor materials,

but due to incorrect measurement setup.

This guide explains the key elements of a reliable Hall effect measurement setup,

focusing on sample geometry, electrical contacts, and common error sources.

1. Why Hall Measurement Setup Matters More Than You Think

The Hall voltage is typically small.

It is often orders of magnitude lower than the longitudinal voltage.

As a result, Hall measurements are highly sensitive to:

- Contact placement

- Sample geometry

- Magnetic field alignment

- Electrical noise and offsets

A correct setup is essential for meaningful results.

2. Sample Geometry: Hall Bar vs. Van der Pauw

Hall Bar Geometry

Hall bar structures are common in semiconductor research.

Advantages:

- Well-defined current paths

- Direct extraction of Hall and longitudinal resistances

- Suitable for temperature and field sweeps

Limitations:

- Requires microfabrication

- Sensitive to dimensional inaccuracies

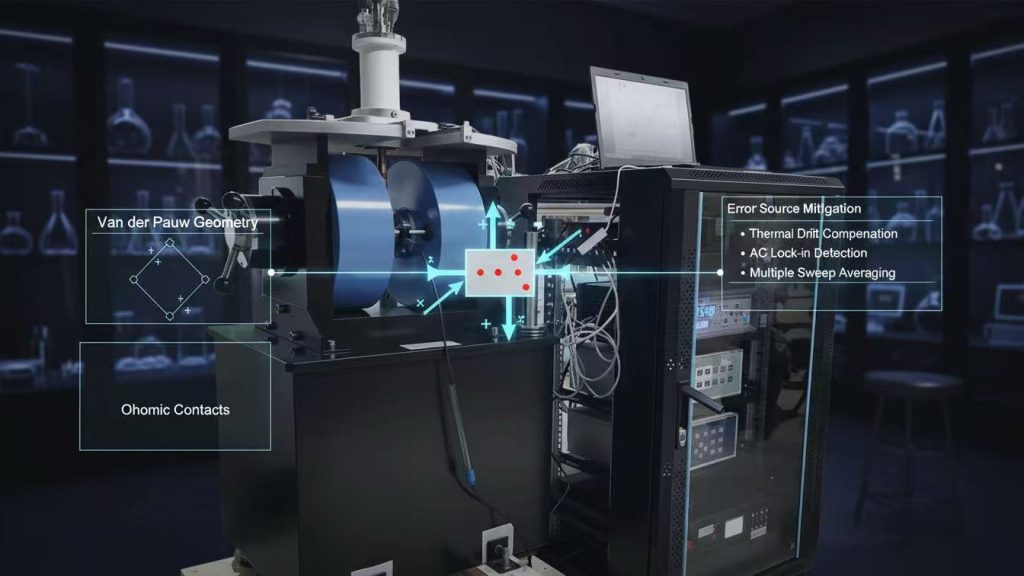

Van der Pauw Geometry

The Van der Pauw method works with arbitrarily shaped samples.

Advantages:

- Minimal fabrication requirements

- Useful for bulk or irregular samples

Limitations:

- Sensitive to contact size and symmetry

- Requires careful averaging and correction

Choosing the correct geometry depends on material type and fabrication capability.

3. Electrical Contacts: Small Details, Big Consequences

Poor electrical contacts are a leading source of error.

Common issues include:

- Large or asymmetric contacts

- High contact resistance

- Non-ohmic behavior

Best practices:

- Use small, well-defined contacts

- Ensure ohmic contact behavior

- Place contacts symmetrically whenever possible

Contact errors often appear as offset voltages or unstable readings.

4. Magnetic Field Alignment and Polarity

Hall voltage depends on the magnetic field component perpendicular to the sample.

Misalignment leads to:

- Reduced effective field

- Mixing of longitudinal and Hall voltages

Standard techniques include:

- Reversing magnetic field polarity

- Averaging positive and negative field data

- Verifying sample orientation

Accurate field control is as important as sample preparation.

5. Temperature Control and Measurement Stability

Temperature affects:

- Carrier mobility

- Contact resistance

- Sample resistivity

Uncontrolled temperature drift introduces systematic errors.

Stable temperature control and monitoring are critical,

especially for low-temperature or long-duration measurements.

6. Common Error Sources in Hall Measurements

Typical error sources include:

- Offset voltages from contact asymmetry

- Thermal EMFs in wiring

- Magnetic field non-uniformity

- Electrical noise from current sources

Many of these errors can be reduced by:

- Field reversal techniques

- Low-noise current sources

- Proper shielding and grounding

7. Why Integrated Measurement Systems Help

A complete Hall measurement setup involves more than a magnet.

An integrated system typically includes:

- Stable magnetic field generation

- Low-noise current source

- Sensitive voltage measurement

- Temperature control and logging

Using mismatched components often increases setup complexity and uncertainty.

8. Practical Hall Measurement Solutions

Cryomagtech provides integrated solutions for Hall effect measurements, including:

- Hall Effect Measurement Systems

- Electromagnets and Helmholtz coils

- Low-noise excitation and measurement electronics

- Optional temperature control and automation

👉Product link placeholder: Hall Effect Measurement System with Magnet Solutions

References

- Wikipedia – Hall effect

https://en.wikipedia.org/wiki/Hall_effect - IEEE – Hall measurement techniques

https://ieeexplore.ieee.org/

Key Takeaways

- Hall measurements are extremely setup-sensitive

- Geometry and contact quality dominate accuracy

- Field alignment and temperature stability matter

- Integrated systems reduce error and save time

Good Hall data starts with good experimental design.