Three-axis vector magnetic fields are essential in modern laboratories.

They are widely used in IMU and AHRS calibration, magnetometer testing, and anisotropic material research.

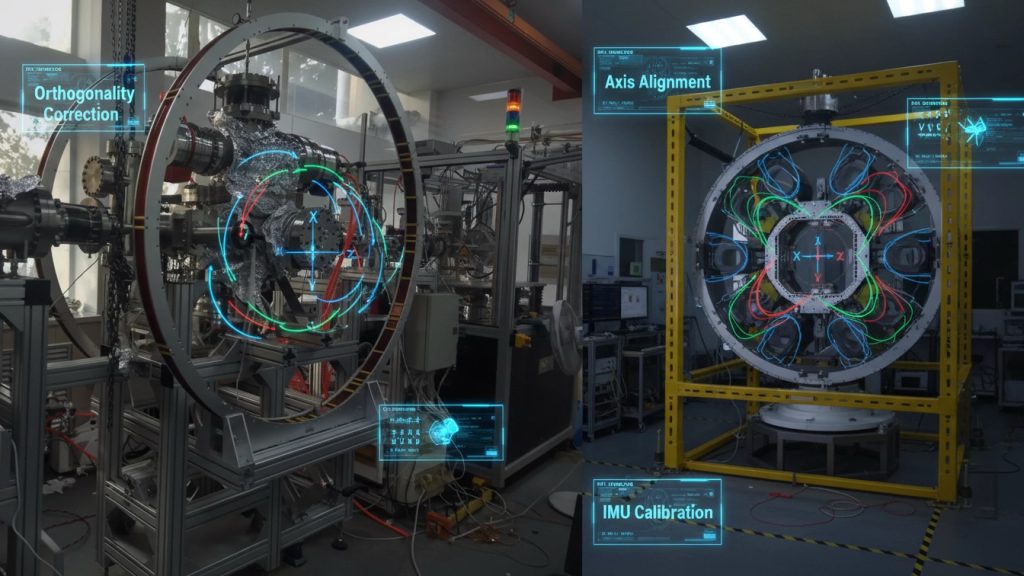

However, generating a clean, orthogonal, and well-calibrated 3-axis magnetic field is not trivial.

This article explains the key coil geometry trade-offs

and outlines a practical calibration workflow for reliable 3-axis field systems.

1. Why 3-Axis Vector Fields Are Different from Single-Axis Systems

A single-axis field focuses on strength and uniformity.

A 3-axis system must also ensure orthogonality and decoupling.

Key additional challenges include:

- Axis misalignment

- Magnetic coupling between coils

- Different field constants on each axis

- Calibration matrix errors

Ignoring these effects leads to systematic measurement errors.

2. Common 3-Axis Coil Geometries

Orthogonal Helmholtz Coil Sets

The most common solution uses three orthogonal Helmholtz coil pairs.

Advantages:

- Excellent field uniformity near the center

- Predictable B/I coefficients

- Scalable size and field range

Trade-offs:

- Mechanical alignment tolerance becomes critical

- Mutual inductance between axes must be managed

- Large systems require rigid frames

Vector Coils with Compact Geometry

Compact vector coils integrate three axes into a smaller volume.

Advantages:

- Reduced footprint

- Faster field switching

- Better integration with fixtures

Trade-offs:

- Reduced uniform volume

- More complex calibration

- Higher sensitivity to manufacturing tolerances

3. Geometry Trade-offs: What Really Matters

When selecting a 3-axis system, geometry choices affect:

- Uniform volume size

- Maximum achievable field per axis

- Thermal behavior at high current

- Ease of calibration and re-calibration

There is no universal “best” geometry.

The right choice depends on sample size, target field, and required accuracy.

4. Mutual Coupling and Axis Crosstalk

In real systems, coils are not independent.

Effects include:

- Field on X changes when Y current is applied

- Phase lag during dynamic field changes

- Drift due to thermal expansion

These effects must be quantified during calibration,

not ignored in specifications.

5. Practical Calibration Workflow for 3-Axis Systems

A reliable calibration process typically includes:

- Mechanical alignment of coil axes

- Measurement of individual B/I coefficients

- Mapping of cross-axis coupling terms

- Construction of a 3×3 calibration matrix

- Validation using rotated sensor orientations

This matrix-based approach is standard in high-accuracy calibration systems.

6. Sensor Placement and Calibration Fixtures

Calibration accuracy depends strongly on sensor positioning.

Best practices include:

- Using precision non-magnetic fixtures

- Positioning sensors at the uniform field center

- Avoiding cable-induced torque or movement

- Controlling temperature during calibration

Small mechanical errors can dominate final accuracy.

7. Software Compensation and Long-Term Stability

Modern 3-axis systems rely on software to:

- Apply calibration matrices in real time

- Compensate slow thermal drift

- Log long-term stability metrics

This is especially important for:

- IMU and AHRS production calibration

- Long-duration material measurements

8. Integrated 3-Axis Solutions for Calibration and Research

Cryomagtech provides integrated solutions for 3-axis vector field generation, including:

- 3-axis Helmholtz and vector coil systems

- Precision current drivers for each axis

- Calibration fixtures and alignment tools

- Control and calibration software

👉Product link placeholder: 3-Axis Helmholtz / Vector Coil Systems & Calibration Solutions

References

- Wikipedia – Helmholtz coil

https://en.wikipedia.org/wiki/Helmholtz_coil - IEEE – Magnetometer calibration and vector field control

https://ieeexplore.ieee.org/

Key Takeaways

- 3-axis fields require geometry and calibration thinking

- Coil layout defines uniformity and coupling behavior

- Calibration matrices are essential for accuracy

- Integrated hardware and software deliver reliable results

Vector magnetic fields are engineered systems—not simple coil assemblies.