Choosing the right magnetic field source is one of the most critical decisions in experimental design.

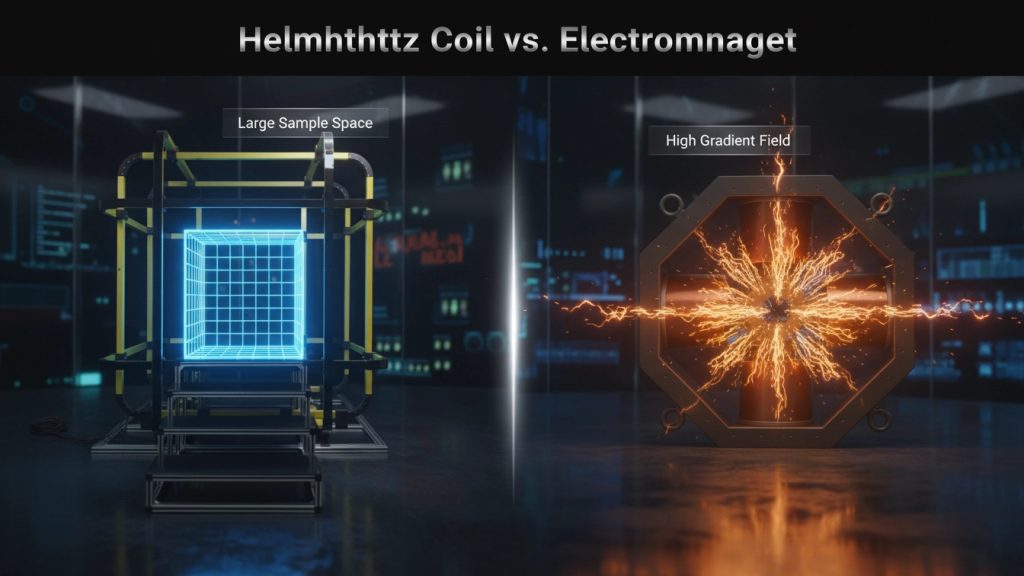

Helmholtz coils and electromagnets can both generate controlled magnetic fields, but they serve very different experimental priorities.

This article breaks down the choice from an application-driven perspective:

sample size, field strength, uniformity, thermal behavior, noise, and scalability.

1. Sample Size and Mechanical Access

Helmholtz Coil

Helmholtz coils provide an open geometry.

The sample is placed at the center of the coil pair, with excellent optical and mechanical access.

This makes them ideal for:

- Sensor calibration

- Magnetometer and IMU testing

- Experiments requiring free space around the sample

Electromagnet

Electromagnets rely on a pole gap.

Sample size is constrained by the gap and pole face geometry.

They are better suited for:

- Compact samples

- Fixtures requiring high force or shielding

- Controlled gap experiments

Key takeaway:

Large or awkwardly shaped samples favor Helmholtz coils.

2. Achievable Field Strength

Helmholtz Coil

Helmholtz coils typically operate from:

- µT to tens of mT

- Occasionally up to ~0.1 T with high power and cooling

They prioritize uniformity over raw field strength.

Electromagnet

Electromagnets can easily reach:

- Hundreds of mT

- Several Tesla (with water cooling and optimized cores)

They are the standard choice for high-field experiments.

Key takeaway:

If field strength is the primary requirement, electromagnets win.

3. Field Uniformity and Usable Volume

Uniformity is often where experiments succeed—or fail.

Helmholtz Coil

Helmholtz coils are designed specifically to maximize uniformity.

They provide a large, well-defined uniform volume, often specified in % or ppm.

This is why they dominate:

- Calibration labs

- Reference measurements

- Background field compensation

Electromagnet

Electromagnet uniformity depends heavily on:

- Pole face shape

- Gap size

- Shimming and mapping

Uniform regions are typically smaller and closer to the pole center.

Key takeaway:

For large uniform volumes, Helmholtz coils are the safer choice.

4. Thermal Behavior and Duty Cycle

Helmholtz Coil

Helmholtz coils are usually air-cooled.

They handle continuous operation well at moderate fields.

At higher currents, thermal drift must be considered.

Electromagnet

Electromagnets often require:

- Water cooling

- Flow monitoring

- Interlock protection

They support high duty cycles but add system complexity.

Key takeaway:

Electromagnets handle higher thermal loads but require infrastructure.

5. Noise and Field Stability

Helmholtz Coil

With a precision current source, Helmholtz coils offer:

- Low noise

- Excellent long-term stability

They are widely used in low-field and noise-sensitive experiments.

Electromagnet

Electromagnets amplify power supply noise into field noise.

This makes current source quality and control electronics critical.

Key takeaway:

Noise-sensitive measurements favor Helmholtz coils with precision drivers.

6. Scalability and System Expansion

Helmholtz Coil

Helmholtz systems scale naturally into:

- 2-axis and 3-axis configurations

- Background field compensation systems

Electromagnet

Electromagnets scale in field strength but are harder to extend into true vector fields.

Key takeaway:

Vector field applications strongly favor Helmholtz coil systems.

Choosing the Right System for Your Experiment

| Requirement | Better Choice |

|---|---|

| Large sample / open access | Helmholtz Coil |

| High magnetic field | Electromagnet |

| Large uniform volume | Helmholtz Coil |

| Compact high-force setup | Electromagnet |

| Low noise, calibration | Helmholtz Coil |

| High duty cycle, high power | Electromagnet |

Product Selection and System Integration

Cryomagtech provides both solutions, optimized for research environments:

Our team supports custom field specifications, uniformity mapping, cooling design, and system integration.

References

- Wikipedia – Helmholtz coil

https://en.wikipedia.org/wiki/Helmholtz_coil - IEEE – Magnetic field generation and measurement

https://ieeexplore.ieee.org/

Final Thoughts

There is no universally “better” magnetic field source.

The correct choice depends on what your experiment truly needs.

Understanding these trade-offs early prevents:

- Incorrect specifications

- Costly redesigns

- Unusable field performance