Selecting a cryogenic temperature controller is rarely just about the controller itself.

In practice, sensor compatibility and control loop behavior determine whether a low-temperature system is stable, repeatable, and publishable.

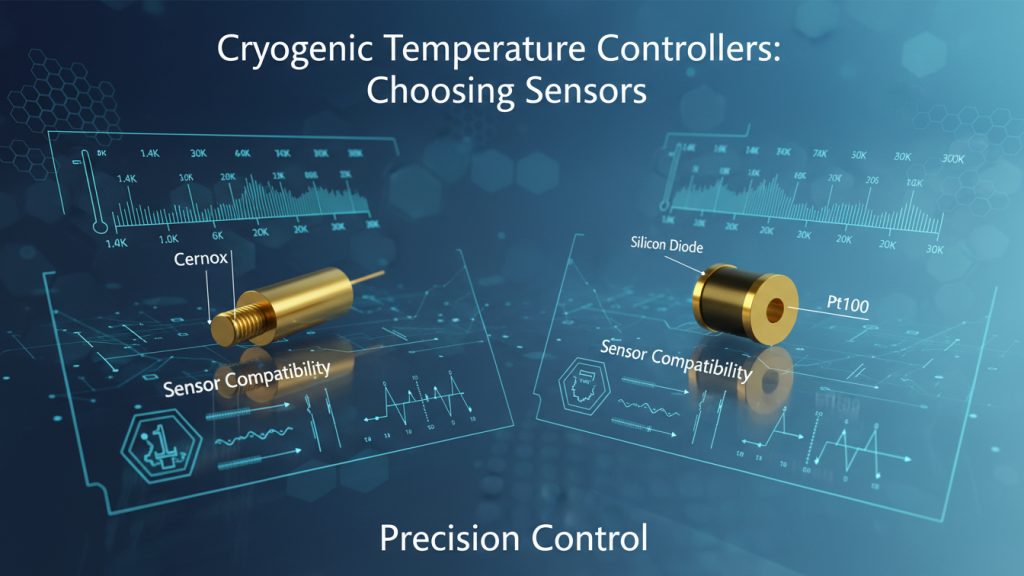

This article explains how to choose between Cernox™, silicon diode, and Pt100 sensors, and how those choices affect control loops, readout current, and PID performance.

1. Why Sensor Choice Matters in Cryogenic Control

At cryogenic temperatures, the sensor is not a passive component.

It directly influences:

- Measurement accuracy

- Noise floor

- Thermal loading

- Control stability

A controller that supports multiple sensor types provides flexibility—but only if the sensor physics are understood.

2. Cernox Sensors: Wide Range, Low Magnetic Sensitivity

Cernox™ sensors are widely used in advanced cryogenic systems.

Key characteristics

- Temperature range: ~300 K down to below 0.1 K

- Low magnetoresistance

- High sensitivity at low temperatures

Practical implications

Cernox sensors are ideal for:

- Cryostats operating across wide temperature ranges

- Experiments involving magnetic fields

- Systems requiring high resolution below 4 K

They typically require low excitation currents to minimize self-heating, which must be supported by the controller.

3. Silicon Diode Sensors: Robust and Cost-Effective

Silicon diode sensors remain popular due to their simplicity.

Key characteristics

- Temperature range: ~1.4 K to 500 K

- Voltage-based readout

- Good repeatability above 4 K

Practical implications

Diodes are well suited for:

- General cryogenic monitoring

- Shields, cold plates, and stages

- Cost-sensitive systems

However, diode sensors are more sensitive to magnetic fields and less suitable for ultra-low-temperature control loops.

4. Pt100 Sensors: Precision Above Cryogenic Extremes

Pt100 RTDs are resistance-based sensors standardized at 100 Ω at 0 °C.

Key characteristics

- Best performance above 20–30 K

- Excellent long-term stability

- Linear response

Practical implications

Pt100 sensors are commonly used for:

- Warm stages and temperature transitions

- Cryocooler interfaces

- Systems prioritizing stability over ultra-low temperature

They are not recommended for sub-10 K control.

5. Readout Current and Self-Heating

Sensor excitation current is often overlooked.

At cryogenic temperatures, micro-watts matter.

- Excess current causes self-heating

- Self-heating distorts temperature readings

- Control loops may oscillate

A proper cryogenic temperature controller must provide:

- Programmable excitation current

- Sensor-specific optimization

6. Control Loops and PID Behavior

Temperature controllers rely on PID algorithms, but sensor dynamics matter.

- High sensitivity sensors respond faster

- Slow thermal coupling requires conservative tuning

- Magnetic fields may alter sensor response

Controllers designed for cryogenic use allow:

- Independent PID settings per channel

- Heater range optimization

- Stable long-term operation

7. Matching Controllers and Sensors as a System

The safest approach is to treat the controller and sensor as one system, not separate purchases.

Cryomagtech supports integrated solutions including:

- Cryogenic Temperature Controllers

- Cernox, diode, and Pt100 sensors

- Heater outputs and control optimization

👉 Product link placeholder: Cryogenic Temperature Controllers & Sensors

References

- Wikipedia – Resistance temperature detectors

https://en.wikipedia.org/wiki/Resistance_thermometer - IEEE – Cryogenic temperature measurement techniques

https://ieeexplore.ieee.org/

Final Considerations

Choosing the wrong sensor can:

- Limit usable temperature range

- Increase noise

- Destabilize control loops

Understanding sensor behavior upfront prevents costly redesigns and unreliable data.