Why Superconducting Magnet Power Supplies Are a Different Class

A superconducting magnet power supply is not just a higher-current power source.

It is a core safety component of the entire magnet system.

Unlike resistive magnets, superconducting magnets:

- Store large amounts of energy

- Operate with near-zero resistance

- Can be permanently damaged by improper operation

For this reason, power supplies for superconducting magnets must address protection, ramping control, and safety interlocks as first-class design requirements.

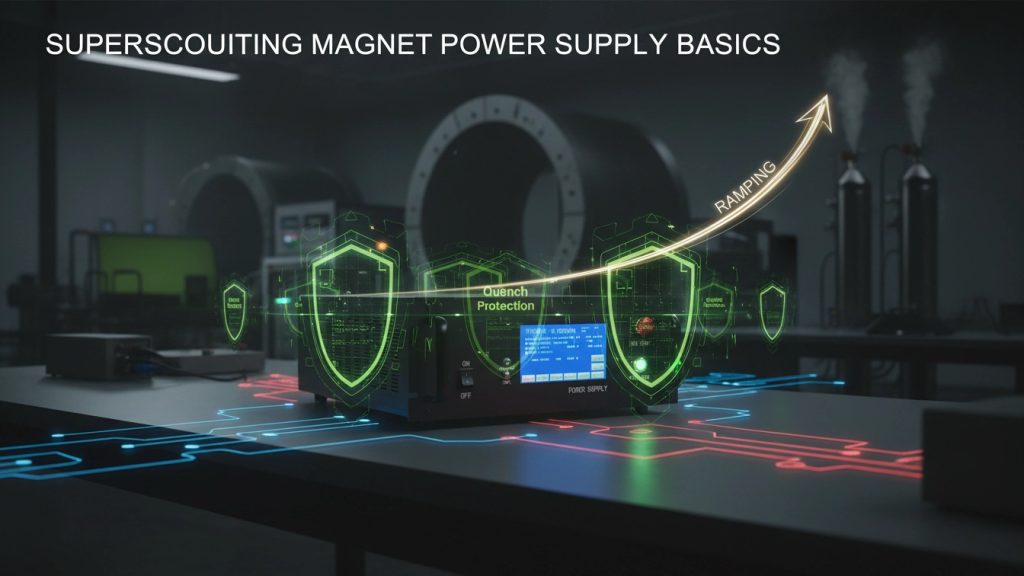

Quench Protection: The Primary Design Priority

A quench occurs when part of the superconducting coil transitions to a normal resistive state.

This can be triggered by:

- Excessive current

- Rapid ramp rates

- Mechanical disturbance

- Thermal instability

When a quench happens, stored magnetic energy is rapidly converted into heat.

Without proper protection, this can result in:

- Coil damage

- Insulation failure

- Cryostat overpressure

Superconducting magnet power supplies therefore integrate:

- Quench detection circuits

- Energy extraction paths

- Controlled current shutdown logic

Quench protection is not optional.

It defines whether a system is safe to operate.

Ramp Rate Control: Protecting the Magnet and the Cryogenics

Ramp rate refers to how quickly current is increased or decreased.

In superconducting systems, ramp rate affects:

- Induced voltages in the coil

- Mechanical stress

- Cryogenic stability

Excessive ramp rates can:

- Trigger quenches

- Overload protection circuits

- Cause thermal gradients in the winding

A superconducting magnet power supply must provide:

- Precisely controlled ramp profiles

- Programmable ramp limits

- Smooth transitions without current steps

These features ensure predictable magnet behavior during operation.

Persistent Mode and Current Stability

Many superconducting magnets operate in persistent mode, where current circulates without an external power supply.

The power supply plays a critical role during:

- Charging the magnet

- Discharging the magnet

- Switching in and out of persistent mode

Key requirements include:

- Extremely low current ripple

- High long-term stability

- Accurate current readback

Poor current control during these phases directly impacts field stability.

Safety Interlocks: Preventing Operator and System Errors

Superconducting magnet systems rely heavily on interlock logic.

Typical interlocks include:

- Cryogenic status (temperature, pressure, helium level)

- Quench detection signals

- Emergency stop inputs

- External facility safety signals

The power supply must respond immediately when an interlock is triggered.

A well-designed interlock system:

- Prevents unsafe operation

- Protects expensive hardware

- Reduces dependence on operator judgment

Integration with Magnet and Cryogenic Systems

A superconducting magnet power supply does not operate in isolation.

It must integrate with:

- Cryostats and refrigerators

- Quench protection units

- Control and monitoring software

This integration requires:

- Reliable communication interfaces

- Clear fault reporting

- Deterministic response behavior

System-level thinking is essential.

Why a Purpose-Built Superconducting Magnet Power Supply Matters

Using a general-purpose power supply for a superconducting magnet is risky.

Dedicated superconducting magnet power supplies are designed with:

- Built-in quench protection logic

- Controlled ramping algorithms

- Comprehensive interlock handling

- High stability current output

👉 Product link placeholder: Cryomagtech Superconducting Magnet Power Supply Solutions

Cryomagtech superconducting magnet power supplies are engineered to support safe, stable, and predictable operation of high-field superconducting magnet systems.

References

- Wikipedia – Superconducting magnet

https://en.wikipedia.org/wiki/Superconducting_magnet - IEEE – Quench detection and protection in superconducting systems

https://ieeexplore.ieee.org/

Final Thoughts

Superconducting magnets demand respect.

Protection, ramping control, and safety interlocks are not accessories.

They are the foundation of reliable and safe magnet operation.

A properly designed superconducting magnet power supply protects:

- The magnet

- The facility

- The people operating the system