Why Magnetic Field Uniformity Is Often Misunderstood

Magnetic field uniformity is one of the most critical specifications in laboratory experiments.

It is also one of the most misunderstood.

Many users request “high uniformity,” but do not define:

- Over what volume

- With which metric

- Using what measurement method

As a result, the delivered system may meet the specification on paper, yet fail in real experiments.

This article explains how to properly specify and verify magnetic field uniformity, using practical definitions and verification methods.

What Does “Uniform Magnetic Field” Actually Mean?

A uniform magnetic field does not mean the field is identical everywhere.

It means:

The magnetic field variation stays within a defined tolerance inside a specified volume.

Uniformity must always include three elements:

- A numerical tolerance

- A spatial volume

- A reference value

Without all three, the specification is incomplete.

Common Uniformity Metrics: ppm vs. Percentage

Uniformity is typically expressed using one of two metrics.

Percentage Over Volume

This is the most common industrial definition.

Example:

±0.1% over a 20 mm × 20 mm × 20 mm volume

This means the field deviation stays within ±0.1% of the nominal field inside that volume.

Parts Per Million (ppm)

ppm-based definitions are used in high-precision applications.

Example:

100 ppm over a 10 mm spherical volume

ppm values highlight small field variations, but they only make sense when the volume is clearly defined.

Defining the Uniform Volume Correctly

The uniform volume is the region where the field must meet the uniformity requirement.

It can be defined as:

- A cube

- A cylinder

- A sphere

- A plane

Best practice is to:

- Match the volume shape to the sample geometry

- Specify the volume center relative to the magnet geometry

A common mistake is defining an unrealistically large uniform volume, which forces unnecessary compromises in field strength.

Measurement Grid and Field Mapping Strategy

Uniformity cannot be verified at a single point.

Proper field mapping requires:

- A predefined grid of measurement points

- Symmetric placement around the center

- Increased density near the edges of the uniform volume

Typical mapping strategies include:

- 1D line scans

- 2D planar grids

- Full 3D volumetric mapping

The mapping resolution should be fine enough to capture local gradients.

Sources of Error in Uniformity Measurements

Several factors can distort uniformity results.

Common sources include:

- Probe positioning error

- Probe calibration uncertainty

- Mechanical misalignment

- Ambient magnetic field interference

Ignoring these effects can lead to overly optimistic uniformity claims.

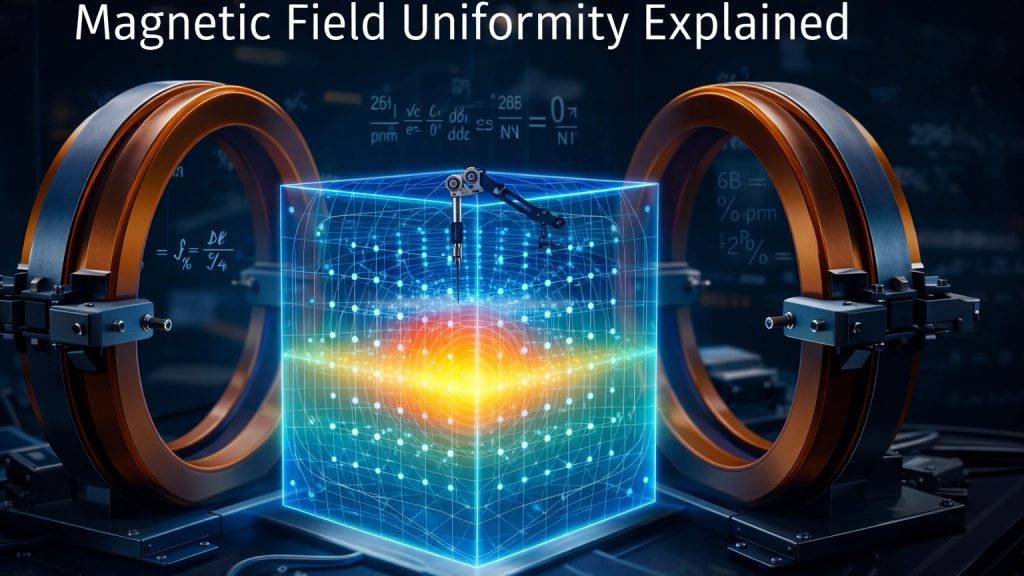

Helmholtz Coils vs. Electromagnets for Uniform Fields

Both system types can produce uniform magnetic fields, but with different trade-offs.

- Helmholtz coils naturally provide a large, well-defined uniform volume

- Electromagnets offer higher field strength but smaller uniform regions

The choice depends on:

- Required field strength

- Sample size

- Uniform volume requirement

👉 Product link placeholder: Cryomagtech Helmholtz Coil and Electromagnet Systems with Field Mapping

Cryomagtech provides magnetic field systems with defined uniform volumes and field mapping data, helping users verify performance before and after installation.

How to Verify Uniformity During Acceptance Testing

Uniformity verification should include:

- Documented mapping procedure

- Raw and processed field data

- Clear calculation method

- Repeatability check

Acceptance testing should reproduce the same mapping volume used in the specification.

References

- Wikipedia – Helmholtz coil

https://en.wikipedia.org/wiki/Helmholtz_coil - IEEE – Magnetic field measurement and uniformity analysis

https://ieeexplore.ieee.org/

Final Takeaway

Magnetic field uniformity is not a single number.

It is a combination of tolerance, volume, and verification method.

Clear definitions prevent mismatched expectations and ensure the magnetic field system actually serves the experiment.