Accurate cryogenic temperature measurement is often limited not by sensor resolution,

but by self-heating caused by the measurement itself.

This issue becomes critical for high-resistance cryogenic thermometers,

especially below 10 K, where even nanowatt-level dissipation can distort readings.

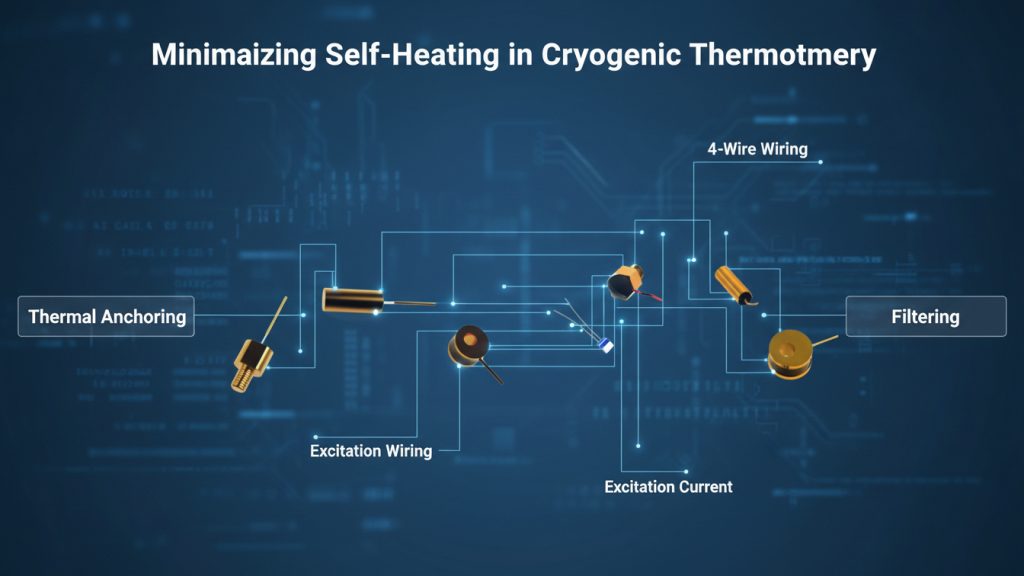

This article explains why self-heating occurs and how to minimize it through

excitation current control, wiring techniques, filtering, and thermal anchoring.

1. Why Self-Heating Matters in Cryogenic Thermometry

Self-heating occurs when electrical power dissipated in a thermometer raises its actual temperature.

At cryogenic temperatures:

- Sensor resistance often increases sharply

- Thermal conductivity to the bath becomes very small

As a result, even microamp-level excitation currents can cause measurable temperature offsets.

2. Excitation Current: Less Is Almost Always Better

The most direct way to reduce self-heating is lowering the excitation current.

Best practices:

- Use the lowest current that maintains acceptable signal-to-noise ratio

- Avoid fixed currents across wide temperature ranges

- Prefer adaptive or range-dependent excitation

For high-resistance sensors, current levels often fall in the:

- 10 nA – 1 µA range

Modern cryogenic temperature monitors support ultra-low, stable excitation currents for this reason.

3. Four-Wire Measurement to Eliminate Lead Resistance

Two-wire measurements introduce additional power dissipation and systematic error.

A four-wire (Kelvin) configuration:

- Separates current injection and voltage sensing

- Eliminates lead resistance from the measurement

- Reduces unnecessary Joule heating in the sensor leads

This method is strongly recommended for:

- Cernox sensors

- Ruthenium oxide sensors

- High-value thermometers below 20 K

4. Wiring Choice and Thermal Anchoring

Wiring plays a dual role:

- Electrical signal transmission

- Thermal conduction into the sensor

Key guidelines:

- Use low-thermal-conductivity wires (e.g., manganin, phosphor bronze)

- Minimize wire cross-section where noise allows

- Add thermal anchor points at intermediate temperature stages

Proper anchoring allows heat generated in the leads to dissipate before reaching the sensor.

5. Filtering High-Frequency Noise

Electrical noise contributes indirectly to self-heating by increasing effective RMS current.

Recommended techniques:

- Low-pass RC filters near room temperature

- Cold filters near the cryogenic stage for sensitive measurements

- Twisted pairs and shielding to reduce pickup

Filtering improves both:

- Measurement stability

- True sensor temperature accuracy

6. Balancing Noise, Stability, and Heating

Reducing excitation current always increases noise.

The practical goal is not zero heating, but:

- Stable readings

- Reproducible temperature values

- Acceptable measurement bandwidth

Modern cryogenic temperature monitors allow users to tune:

- Excitation current

- Measurement averaging

- Filter bandwidth

7. Instrumentation Designed for Low Self-Heating

Minimizing self-heating requires system-level design, not just sensor choice.

Cryomagtech provides:

- Cryogenic thermometers and sensors

- Low-noise temperature monitors

- Controllers optimized for ultra-low excitation currents

👉 Product link placeholder: Cryogenic Thermometers & Temperature Monitors

References

- Wikipedia – Cryogenic temperature measurement

https://en.wikipedia.org/wiki/Cryogenics - IEEE – Low-temperature sensor measurement techniques

https://ieeexplore.ieee.org/

Key Takeaways

- Self-heating limits accuracy at low temperatures

- Excitation current must scale with resistance and temperature

- Wiring, filtering, and thermal anchoring are equally important

Careful design ensures the thermometer measures the sample—not itself.