Introduction

Three-axis magnetic field generation is a core requirement for AHRS, magnetometer, and IMU calibration laboratories.

It is also one of the most misunderstood system designs.

Many specifications mention “3-axis field capability,” but fail to define uniformity volume, axis coupling, calibration accuracy, and stability. This article explains the key design trade-offs behind 3-axis Helmholtz coils and vector coil systems, and how these choices impact real calibration results.

1. What Does “3-Axis Magnetic Field” Really Mean?

A true 3-axis magnetic field system must independently generate Bx, By, and Bz with:

- Defined field strength on each axis

- Known uniformity inside a usable volume

- Minimal cross-axis coupling

In practice, this is achieved using three orthogonal coil pairs, most commonly based on Helmholtz or modified Helmholtz geometries.

Wikipedia provides a general overview of Helmholtz coils and their uniform field properties:

https://en.wikipedia.org/wiki/Helmholtz_coil

2. Vector Coil vs. Simple 3-Axis Helmholtz Design

Not all 3-axis systems are equal.

Standard 3-Axis Helmholtz Coils

Advantages:

- Simple geometry

- Predictable field equations

- Good uniformity near the center

Limitations:

- Larger physical size

- Limited flexibility for compact DUTs

Vector Coil Systems

Advantages:

- Compact structure

- Higher field efficiency in limited space

- Easier integration with fixtures and probe stations

Trade-offs:

- More complex mechanical design

- Stronger axis coupling

- Higher calibration and compensation requirements

Vector coils are preferred in sensor calibration rigs, while Helmholtz coils dominate reference-grade calibration volumes.

3. Axis Coupling and Orthogonality Errors

One of the biggest hidden problems in 3-axis systems is axis coupling.

When current flows in one axis:

- Mechanical misalignment can generate unwanted fields on other axes

- Magnetic materials near the coils distort orthogonality

- Wiring asymmetry introduces repeatable errors

These effects directly impact IMU calibration accuracy, especially for heading and tilt estimation.

High-end systems measure and compensate coupling using matrix-based calibration models, a concept well established in sensor calibration literature and IEEE measurement standards.

4. Uniformity Volume vs. DUT Size

Uniformity is meaningless without volume.

Key questions every calibration lab should ask:

- What is the usable uniform region size?

- Is uniformity specified as peak-to-peak or RMS?

- Is it measured with a probe or simulated only?

For AHRS and magnetometer calibration, the DUT and fixture must fit entirely inside the specified uniform volume. Otherwise, calibration errors appear even if the system “meets spec.”

5. Calibration Rigs and Mechanical Design

The coil is only half the system.

A proper 3-axis calibration rig must include:

- Rigid DUT mounting with repeatable positioning

- Known rotation axes for heading and tilt calibration

- Non-magnetic structural materials

Mechanical instability often limits accuracy more than electrical noise, especially in multi-position calibration sequences.

6. Control Electronics and Field Stability

Field generation accuracy depends on more than geometry.

Critical factors include:

- Current driver resolution and drift

- Long-term stability during calibration sequences

- Optional closed-loop field feedback

Open-loop systems are acceptable for short tests.

Closed-loop systems are preferred for high-accuracy or long-duration calibration, especially when environmental magnetic noise is present.

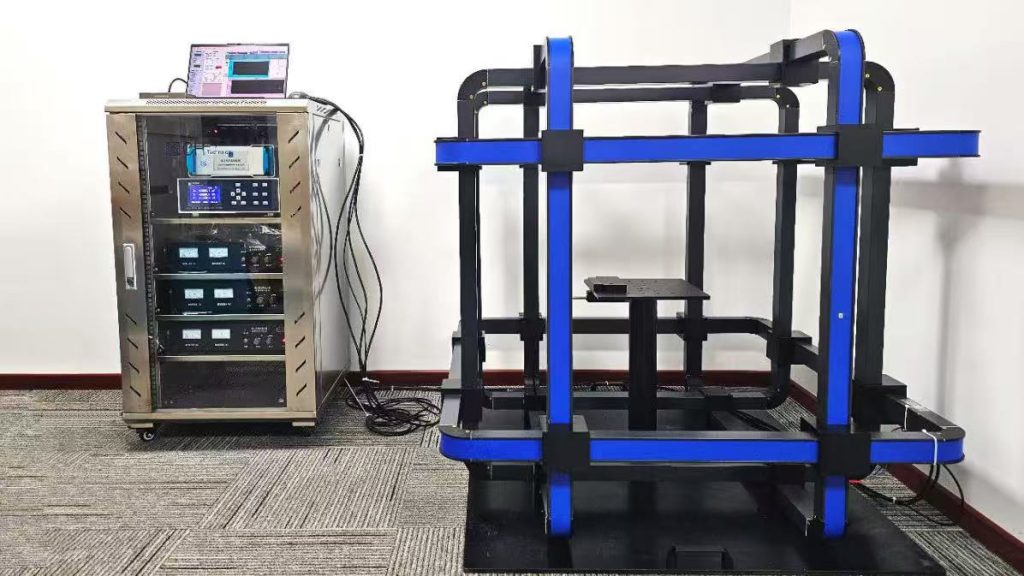

Cryomagtech 3-Axis Field Solutions

Cryomagtech provides 3-axis Helmholtz coil and vector coil systems designed for calibration and test laboratories, featuring:

- Precisely aligned orthogonal coil structures

- Defined uniformity volumes with test data

- Low-drift current drivers

- Optional closed-loop magnetic field control

- Integration support for AHRS, IMU, and magnetometer calibration rigs

👉 Cryomagtech 3-Axis Helmholtz / Vector Coil Product

These systems are widely used in sensor calibration, navigation testing, and laboratory reference setups.

Conclusion

3-axis magnetic field generation is not just about adding three coils.

Real performance depends on:

- Geometry and alignment

- Uniformity volume definition

- Axis coupling control

- Calibration rig design

- Driver and control stability

Understanding these trade-offs helps laboratories choose the right solution—and avoid calibration errors that no amount of software can fix later.

References

- Helmholtz coil fundamentals: https://en.wikipedia.org/wiki/Helmholtz_coil

- General principles of multi-axis sensor calibration summarized in IEEE measurement literature