When specifying an electromagnet, researchers often focus on target field strength.

However, many projects fail or require costly redesigns because two parameters were poorly defined:

aperture and pole gap.

These dimensions directly determine whether a magnet can reach the required field, accommodate the sample, and remain stable during long measurements.

This article explains how aperture and pole gap affect magnetic performance, and how to specify them correctly.

1. What Do “Aperture” and “Pole Gap” Really Mean?

Although often used interchangeably, they describe different constraints.

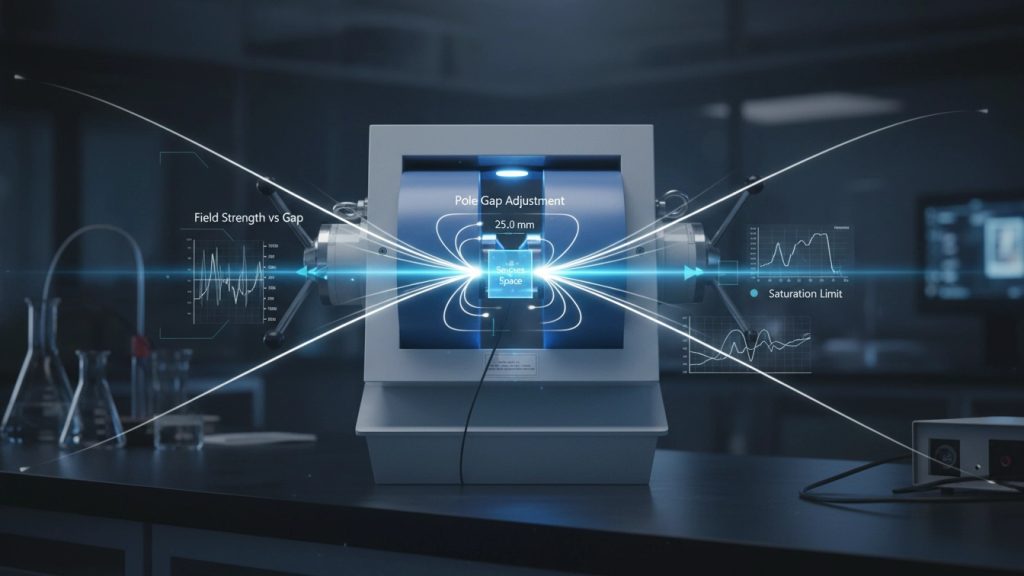

- Pole gap: the distance between opposing pole faces

- Aperture: the usable space available for samples, probes, cryostats, or fixtures

In practice, the required aperture usually sets the minimum pole gap.

Once this is fixed, the achievable field strength becomes an engineering problem.

2. Why Larger Pole Gaps Reduce Maximum Field

Magnetic field strength in an electromagnet is limited by:

- Coil ampere-turns

- Magnetic circuit reluctance

- Core material saturation

Increasing the pole gap increases magnetic reluctance.

As a result, much higher current is required to reach the same field.

At some point, the iron poles approach magnetic saturation, and further current produces diminishing returns.

This is the most common reason users fail to reach their target field.

3. Pole Face Shape: Flat, Tapered, or Profiled?

Pole face geometry strongly affects both field strength and uniformity.

Flat Pole Faces

- Simple and robust

- Limited field concentration

- Suitable for moderate fields and larger gaps

Tapered or Conical Poles

- Higher local field

- Reduced uniform volume

- Increased sensitivity to alignment

Profiled Poles (Custom Shaping)

- Optimized trade-off between uniformity and strength

- Requires careful simulation and machining

Choosing pole shape is always application-driven.

4. Leakage Flux and Fringe Fields

As aperture increases, leakage flux and fringe fields become more significant.

This can lead to:

- Reduced usable field uniformity

- Increased magnetic interference with nearby instruments

- Unexpected forces on metallic fixtures

Proper yoke design and shielding strategies are essential in large-aperture systems.

5. Sample Access vs. Field Performance: The Core Trade-off

Every electromagnet design balances:

- Required sample size

- Probe or cryostat access

- Optical paths or wiring clearance

- Maximum achievable field

There is no universal “best” aperture.

The correct choice depends on what must physically fit inside the gap.

Over-specifying aperture is one of the most expensive mistakes.

6. Practical Specification Checklist

Before requesting a quotation, define:

- Required uniform field region (dimensions)

- Maximum sample and fixture size

- Target field strength at the sample center

- Acceptable field uniformity

- Measurement duration and duty cycle

Providing these parameters dramatically improves design accuracy.

7. How Cryomagtech Supports Custom Electromagnet Design

Cryomagtech provides application-driven electromagnet solutions, including:

- Aperture and pole gap optimization

- Custom pole face shaping

- Field simulation and mapping support

- Integration with power supplies and control software

👉 Product link placeholder: Cryomagtech Electromagnet Systems

Clear specifications lead to reliable performance and predictable results.

References

- Wikipedia – Electromagnet fundamentals

https://en.wikipedia.org/wiki/Electromagnet - IEEE – Magnetic circuit and saturation concepts

https://ieeexplore.ieee.org/

Key Takeaways

- Aperture and pole gap directly limit achievable field strength

- Larger gaps require higher current and careful saturation management

- Pole face geometry strongly affects uniformity and access

- Clear specifications prevent costly redesigns

Electromagnet performance is defined long before fabrication begins.