Why Proper Electromagnet Specification Matters

Many electromagnet projects fail for one simple reason:

the specification was incomplete or ambiguous.

Researchers often describe the target magnetic field very clearly.

However, key geometric parameters are missing.

As a result:

- The field uniformity is worse than expected

- The sample does not fit inside the magnet

- The working distance is insufficient

- Redesign becomes unavoidable

This article explains how to specify an electromagnet correctly, using four essential parameters:

pole gap, pole face, aperture, and working distance.

Pole Gap: Defining the Magnetic Field Space

The pole gap is the distance between the two magnetic poles.

It directly determines:

- Maximum achievable field

- Field uniformity

- Available space for the sample

A smaller gap allows higher magnetic fields at lower power.

A larger gap increases flexibility but reduces field strength.

Common mistake:

Specifying the field strength without defining the required pole gap.

Practical tip:

Always specify the required field at the actual pole gap, not at an idealized value.

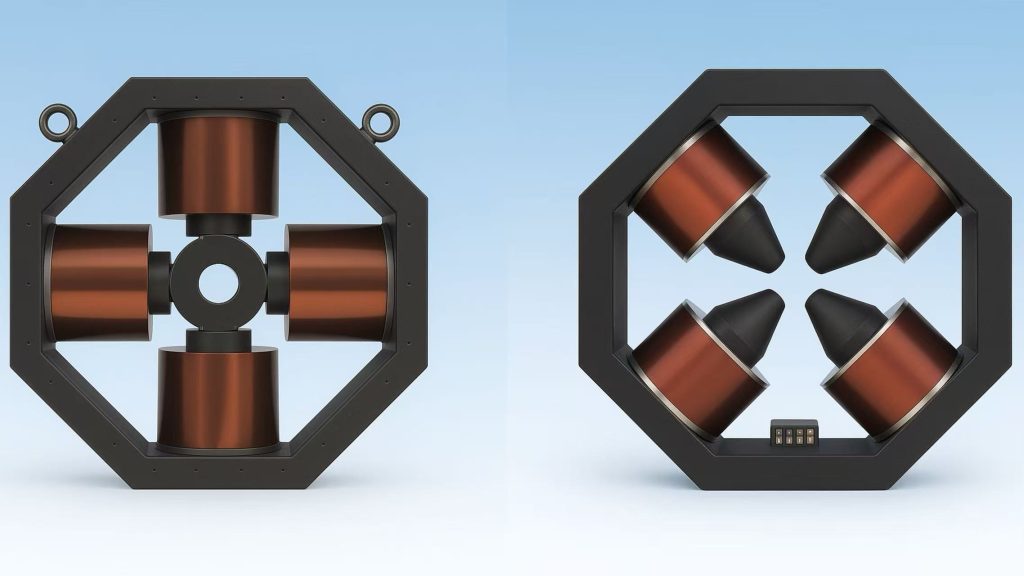

Pole Face: Controlling Field Uniformity

The pole face refers to the shape and size of the pole surfaces.

Pole face geometry affects:

- Field homogeneity

- Edge effects

- Sensitivity to misalignment

Typical pole face options include:

- Flat pole faces for general use

- Chamfered or profiled faces for improved uniformity

Key question to answer:

What is the required uniform volume, and how is it defined?

Uniformity should always be expressed with:

- Percentage (±1%, ±0.5%, etc.)

- Spatial definition (diameter, cube, or plane)

Aperture: Ensuring Mechanical Compatibility

The aperture is the clear opening available for the sample and fixtures.

It must account for:

- Sample size

- Sample holder

- Probes, wiring, or cryostats

A common oversight is ignoring future upgrades.

Today’s experiment may require more space tomorrow.

Best practice:

Specify the minimum required aperture, plus reasonable margin.

Working Distance: The Hidden Constraint

The working distance is the usable space between the pole face and the sample.

This parameter is critical for:

- Optical access

- Probe clearance

- Motion stages

Many users confuse working distance with pole gap.

They are not the same.

Working distance must consider:

- Sample thickness

- Mounting hardware

- Adjustment tolerance

If working distance is not specified, the magnet may be unusable for the intended setup.

Putting It All Together: A Simple Specification Template

When requesting an electromagnet quotation, include the following:

- Target magnetic field and stability

- Pole gap at which the field is required

- Pole face shape and uniformity definition

- Required aperture

- Minimum working distance

- Duty cycle and cooling preference

👉 Product link placeholder: Cryomagtech Custom Electromagnet Solutions

Cryomagtech supports both standard and fully customized electromagnet designs, helping users translate experimental needs into manufacturable systems.

References

- Wikipedia – Electromagnet

https://en.wikipedia.org/wiki/Electromagnet - IEEE – Magnetic field design and electromagnet engineering

https://ieeexplore.ieee.org/

Final Thoughts

An electromagnet is not defined by field strength alone.

Geometry defines whether the field is usable.

Clear specifications save:

- Time

- Cost

- Iterations

Most importantly, they ensure the delivered system matches the experiment.