Magnetic field uniformity claims are easy to make.

Proving them is much harder.

For research labs and procurement teams alike,

field mapping is the only credible way to demonstrate magnetic field quality.

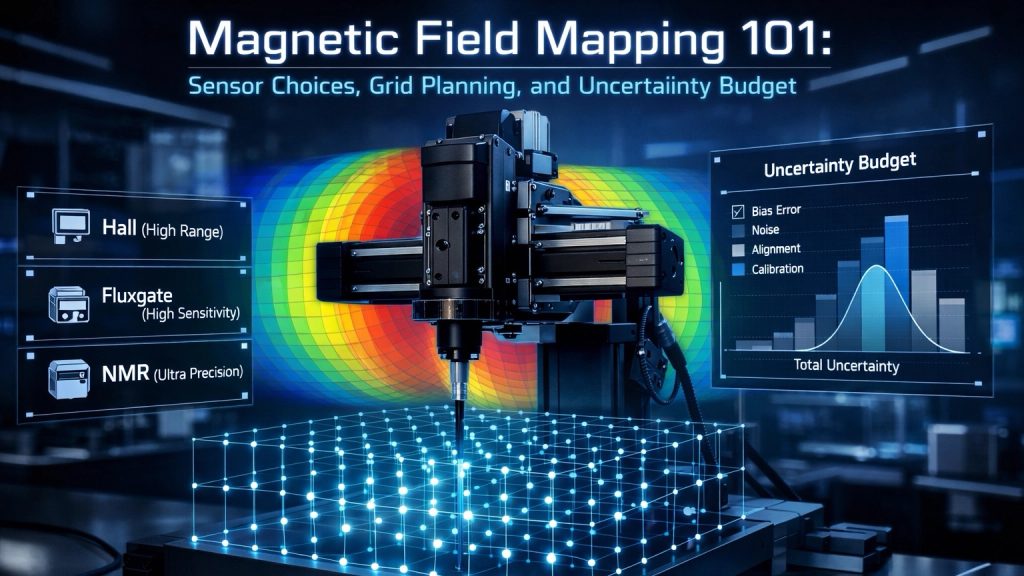

This article explains how to design a practical magnetic field mapping workflow,

from sensor selection to grid planning and uncertainty budgeting.

1. What Is Magnetic Field Mapping and Why It Matters

Magnetic field mapping is the process of measuring the spatial distribution of a magnetic field over a defined volume.

It is used to:

- Verify field uniformity specifications

- Define usable uniform volume

- Support acceptance testing and documentation

- Ensure reproducibility of experiments

Without mapping data, “uniformity” is only a theoretical promise.

2. Choosing the Right Magnetic Field Sensor

Sensor choice defines both measurement credibility and uncertainty floor.

2.1 Hall Sensors

Best for:

- mT to multi-Tesla fields

- General-purpose mapping

- Cost-sensitive setups

Limitations:

- Offset drift

- Temperature sensitivity

- Limited absolute accuracy without calibration

Hall probes are commonly used for routine acceptance mapping of electromagnets and Helmholtz coils.

2.2 Fluxgate Sensors

Best for:

- µT to low-mT fields

- Background field compensation studies

- Low-field uniformity verification

Advantages:

- Excellent low-field sensitivity

- Good stability over time

Limitations:

- Limited upper field range

- Sensitive to alignment errors

Fluxgates are ideal when Earth-field-level accuracy is required.

2.3 NMR Probes

Best for:

- Absolute field accuracy

- Reference calibration points

Advantages:

- Extremely high absolute accuracy

- Minimal drift

Limitations:

- Requires strong, homogeneous fields

- Not suitable for large-area scanning

NMR probes are often used to anchor uncertainty budgets rather than perform full mappings.

3. Grid Planning: How Many Points Are Enough?

Grid design determines whether mapping data is meaningful or misleading.

Key Principles

- Mapping resolution must match field gradient scale

- Uniform volume edges require higher point density

- Symmetry can reduce total point count

A common mistake is using too few points and assuming smooth interpolation.

Typical Grid Strategies

- 1D axis scans for quick checks

- 2D planar grids for aperture systems

- 3D volumetric grids for Helmholtz and vector coil systems

The larger the claimed uniform volume,

the more demanding the grid requirements become.

4. Positioning Error: The Silent Uncertainty Source

Positioning error often dominates the uncertainty budget.

Sources include:

- Probe holder tolerances

- Mechanical sag

- Manual placement repeatability

Even a 1 mm position error can produce significant field uncertainty in high-gradient regions.

Good mapping setups treat mechanical alignment as a first-class specification.

5. Repeatability and Temporal Stability

Field mapping is not a single measurement.

You must verify:

- Short-term repeatability

- Drift over time

- Sensitivity to coil temperature

Repeated scans at selected points are essential for validating stability claims.

6. Building an Uncertainty Budget

A credible field mapping report includes an uncertainty budget.

Typical contributors:

- Sensor accuracy and calibration

- Temperature effects

- Positioning uncertainty

- Measurement noise

- Current stability

Ignoring uncertainty does not remove it.

It only hides it.

7. From Mapping to Acceptance Testing

For procurement and system acceptance, mapping data should define:

- Uniform volume size

- Maximum deviation (% or ppm)

- Measurement conditions

- Repeatability metrics

This transforms “uniformity” from marketing language into a verifiable specification.

8. Practical Mapping Solutions and Services

Cryomagtech supports magnetic field mapping through:

- Helmholtz and electromagnet systems designed for accessible mapping

- Field mapping fixtures and probe holders

- Optional mapping data and acceptance documentation

👉 Product / Service link placeholder: Field Mapping Accessories & Acceptance Testing Support

References

- Wikipedia – Magnetic field measurement fundamentals

https://en.wikipedia.org/wiki/Magnetic_field - IEEE – Precision magnetic measurement techniques

https://ieeexplore.ieee.org/

Key Takeaways

- Field mapping is the only proof of uniformity

- Sensor choice defines accuracy limits

- Grid planning must match gradient scale

- Positioning errors dominate uncertainty

- Acceptance testing requires documented uncertainty

If you cannot explain how uniformity was measured,

you probably cannot defend it.